Zhuzhou MMM New Material Co., Ltd.

Since inception, ZHUZHOU MMM NEW MATERIAL CO., LTD. is always targeted to be an excellent supplier of cutting tools. We continuously improve product performance, product quality

controls, company’s management and team building.

The company has a high quality and professional technical team

engaged in machinery industry for many years. On the basis of

giving full play to the advantages of its technical service

ability, we have been formed full range of products from blank to

product, primary to high precision and so on which are including

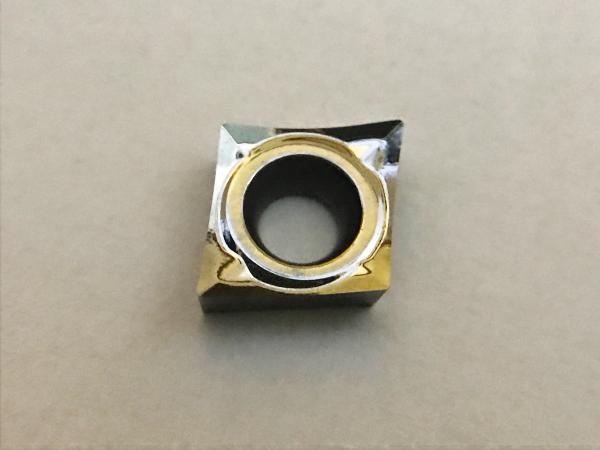

saw brazed tip, brazed tip, insert, CNC tool, tool system and solid

carbide etc. At the same time, we also have ability to provide

customers with customized cutting tools, design, customization and

OEM services according to the actual needs of customers.